Get the Collector's Edge

Subscribe for exclusive, behind-the-scenes access to our workshop. Discover the creation of new models and receive subscriber-only best deals.

Fully Functional Miniature Weapon Models Crafted with Exceptional Quality and a Lifetime Service Guarantee

As a child, watching the How It’s Made TV show was one of my favorite things. I have created similar content today about my miniature weapons production. I’m excited to share all the details of the process, from creating the miniature models to making cartridges for them, packaging them, and everything else that goes into assembling a kit ready to be shipped to our customers. It’s a time-consuming process, but we take pride in producing high-quality miniature weapons that our customers can enjoy. I’m happy to share my passion and process with you.

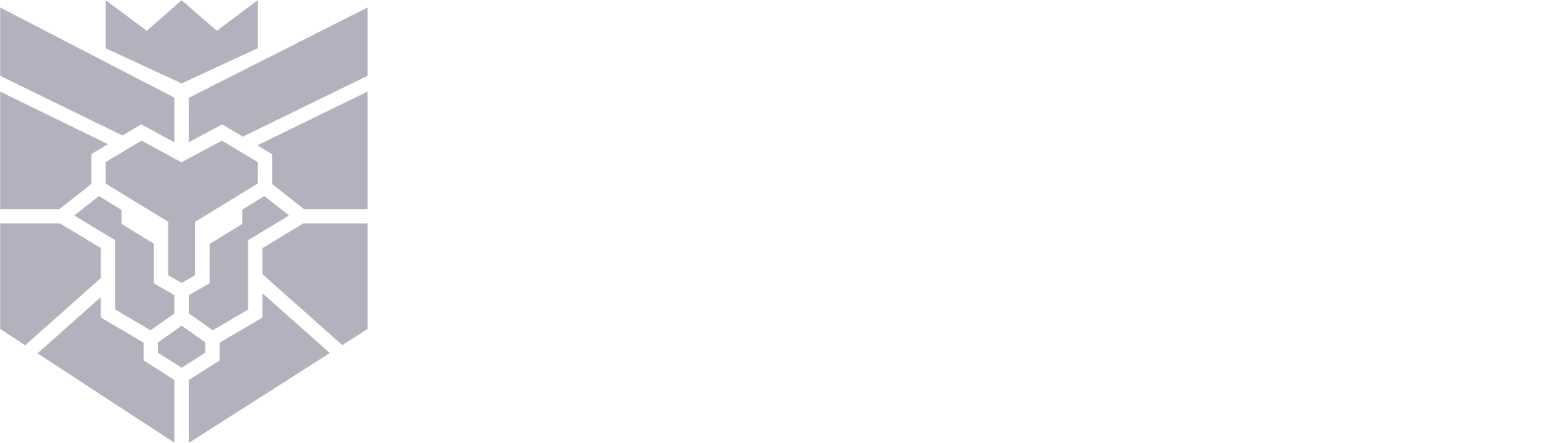

1. We design a future 3D gun model

with all the details

2. We create a gun model

PROTOTYPE

3. We conduct testing and

make necessary improvements

Sometimes, we must return to the drawing board several times until we create a model that meets our high-quality standards. This process can take a few months, especially for more complex models. In some cases, it may even take over a year! But we believe it’s worth the effort to bring you the best products. Adding a new model to our collection is a big undertaking, but we’re always excited about it. We’re really proud of the variety of models we offer, and we hope you enjoy them as much as we do!

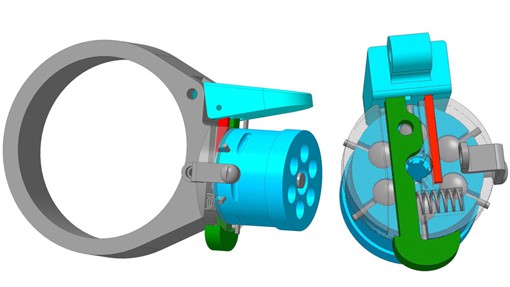

To create a miniature gun, we follow a process where we manufacture each metal part of the gun individually. This is done to ensure that each part is of the highest quality and that the final product is functional and visually appealing. By creating each part separately, we can pay close attention to the details of each piece, ensuring that the result is a finely crafted miniature gun.

At the next stage of our production process, we carefully assemble the model by fitting each separate part together. We pay close attention to the details and ensure each component is precisely fitted. Our team of experts then creates custom springs for each product, which helps to ensure that the mechanism functions smoothly and reliably.

We understand that even the slightest deviation of a hundredths of a millimeter can significantly impact our products’ performance. Therefore, we take great care to ensure that every aspect of our production process is meticulously executed to meet our high-quality standards.

After the model is assembled and sent to the quality control department for testing. We thoroughly check the model’s quality, including its appearance, shooting capabilities, and the functionality of all its mechanisms.

Then, the model goes back to the assembly shop. Here, the model is polished to make it look like the picture.

We pack the model in a wooden box. We add all the necessary accessories. All the models come with ammo and ramrod made by ourselves.

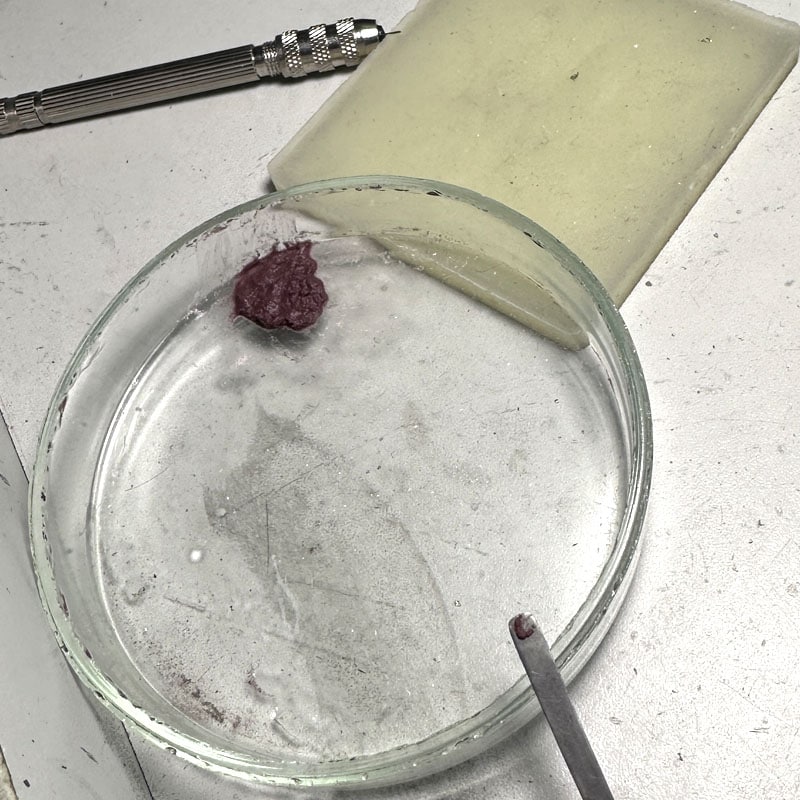

In 2015 we began creating cartridges for our first 1mm Gold Derringer. These centerfire cartridges were produced by turning brass sleeves on a lathe. We conducted multiple experiments with different explosive mixtures before choosing a classic recipe similar to that used for pistons and firecrackers.

We currently use high-quality steel balls made of hardened steel, typically used for bearing production. Initially, we used cartridges made in Austria when we started creating our first 2mm pinfire models.

However, we noticed that their quality deteriorated over time, which led us to develop our own technology to produce these cartridges. Our goal was to ensure that our models would not be negatively impacted by cartridges that misfire, as this would ruin the overall impression of our products. As a result, we developed a reliable cartridge production process that guarantees the highest quality for our customers.

Our life hack: to charge with a wet mixture to make the process safer. When the mixture dries, it becomes highly flammable.

We add steel balls for the live version of cartridges before the mixture has completely dried. After that, we dry the charged cartridges well for two days, using huge sorbent tablets to remove excess moisture.

We began to produce our centerfire cartridges similarly. My team insisted on their development. Because with the creation of a new ammunition standard, the range of models we could take into development expanded for us. Because the design of many types of weapons excludes the possibility of reworking the mechanism for a pinfire cartridge. From the beginning of our work, we tried to keep the proportions similar to the originals and have the most realistic appearance of the miniatures.

We also develop wooden boxes for storing miniatures for each of our models.

Next, depending on the box’s design, we cut the flaps on a laser or a CNC machine and then laser-engrave the logo. We fit the details manually. We polish the wood so that it is pleasant to the touch. And we cover it with special means for protecting wood with or without tinting.

We also make the ramrods included in the kit ourselves. Now we use a stainless steel rod and screw brass tips onto the rod. We buy the rod at the metal depot and make the tips ourselves.

We also include QR-coded instructions in each box now. All you have to do is point your phone at the insert with the QR code in Camera mode and follow the link to the wpolah.com website. The link will direct you to a page with instructions for your model. We have already managed to add instructions and a video demonstrating the model in action for most models to the page.

We carefully pack kit elements to ensure safe transport. We continually expand and improve our model range and use repair experience to create new miniatures. Your commitment inspires us, and most customers return for repeat purchases.

My name is Olha Polah, and I have been working in miniature weapons production since 2015. I started the mini firearms brand and have been running the brand’s Instagram page since 2016. The brand’s miniatures are popular worldwide, with fans in 25+ countries. I became the sole owner of the brand in 2018 and created a comprehensive line of miniatures. More than 60 models of miniature weapons from various historical periods have been created. In November 2023, I was interviewed by Robert Dunn for the GunTech magazine, where I talked about the hardships I had to endure in my business. I also run a newsletter for the brand’s customers, which has evolved into a full-fledged magazine with in-depth articles published on the wpolah.com.

My mission is to make people’s lives more joyful by sharing interesting facts about miniature weapons and inspiring everyone to express themselves.